Department of Sanitation, New York, Upgrades Composting Program

OWNERSHIP: NEW YORK CITY DEPARTMENT OF SANITATION (DSNY)

OPERATOR: DENALI WATER SOLUTIONS, LLC.

LOCATION: STATEN ISLAND, NY, USA

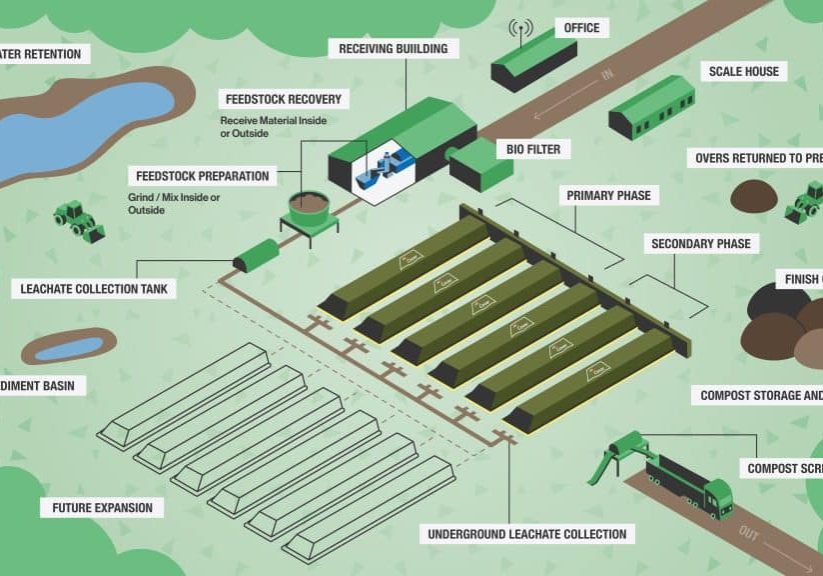

PRODUCT: SG BUNKER® SYSTEM

INPUT QUANTITY: 60,000 TPY

NO. OF SG BUNKER® SYSTEMS: 16 BUNKERS, 16 COVERED, 164 FT. X 27 FT. X 12 FT. EACH

TREATMENT TIME: 8 WEEKS IN 3 PHASES

AERATION: POSITIVE IN-FLOOR

CONTROL PARAMETERS: OXYGEN CONTROL MODE

INPUT MATERIAL: SOURCE SEPARATED ORGANICS (RESIDENTIAL AND COMMERCIAL FOOD WASTE), WOOD CHIPS, GRASS/STRAW, & YARD WASTE

EQUIPMENT: PRE-TREATMENT (TIGER DEPACKAGING MACHINE, GRINDERS) FRONT-END-LOADERS MOBILE SCREEN

END PRODUCT: HIGH-QUALITY FINISHED COMPOST MARKETED AS BIG APPLE COMPOST®

Transformation of the Staten Island Compost Facility

Background

Formal DSNY efforts to recycle organic waste date back to 1990, when the Department collected approximately 3,000 tons of leaves under a pilot project in Staten Island and composted them at its first outdoor composting facility at the Fresh Kills landfill. The Department also composted food waste with other organic material at the Fresh Kills Compost Site from 1991 to 1996, which was collected as part of the Brooklyn Intensive Zone Pilot in Park Slope. From 1993 to 1996, food waste was also collected as part of the Staten Island Institutional Pilot. Though these pilots came to an end, the Department continued composting landscaper and agency yard waste until again piloting food waste composting starting in 2012. The site has been operated by Denali Water Solutions, LLC (formerly WeCare Organics) since 2007 through a contract with DSNY.

Upgrading to SG ADVANCED COMPOSTING™ Technology

To enhance environmental performance, DSNY and its consultants conducted a composting technology evaluation from 2014-2015 to determine the best retrofit solution for the facility. Several critical requirements were identified during the evaluation:

Compliance with stringent air quality standards, focusing on odor and VOC emissions reduction.

Ensuring the separation of process water (leachate) from stormwater.

Producing high-quality compost.

The SG BUNKER® System with GORE® Covers from Sustainable Generation, LLC was selected for its ability to meet these stringent requirements. SG partnered with GHD Engineers and Denali to design and implement the system.

PROJECT GALLERY

SG BUNKER® System at the Staten Island Compost Facility

- default

Project Phases

Phase 1: This phase addressed the geotechnical challenges of operating on a closed landfill. It required careful planning and multiple construction stages to ensure the site’s stability and regulatory compliance.

Phase 2: Construction completed in May 2023, this phase involved building a 16 SG BUNKER® System.

Phase 3: SG provided on-site operator training and remote monitoring support to ensure a smooth transition during the initial operational phase, July 2023.

Phase 4: Site is fully operational.

Conclusion

The transformation of the Staten Island Compost Facility marks a significant step forward in sustainable urban waste management. By adopting the SG BUNKER® System with GORE® Covers, the facility now exceeds regulatory standards while increasing its capacity to process food waste and produce high-quality compost. This project serves as a model for scalable, environmentally responsible composting solutions in urban areas.

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES Across the globe, a…

Celebrating the Season Without Wasting It

Celebrating the Season Without Wasting It The holiday season brings full tables, festive decor,…

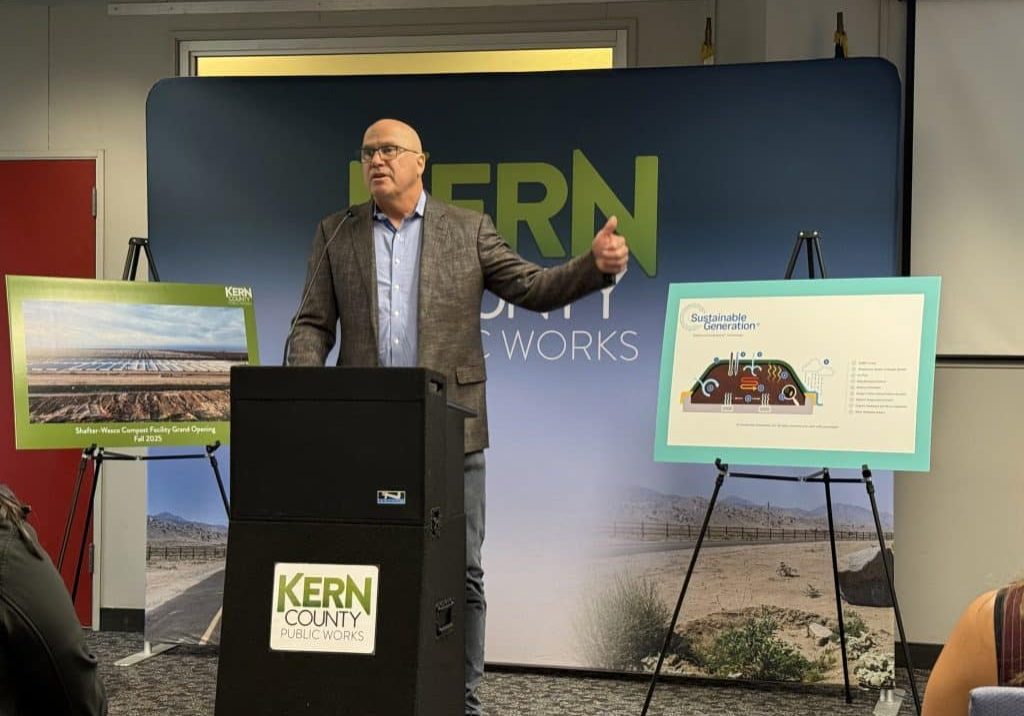

Building a Greener Future Together: Kern County Launches SG-Powered Compost Facility

Sustainable Generation is proud to celebrate the grand opening of the Shafter-Wasco Compost Facility

Making Waves, the Membrane Covered ASP Composting Tsunami

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.