Regional District of Kootenay Boundary expands feedstock capabilities with Sustainable Generation® Technology.

The Regional District of Kootenay Boundary (RDKB) has composted yard and garden waste at the Grand Forks Landfill Facility for more than 25 years using turned windrows. In 2013, as a result of an expanded organics diversion program in the region, residential food waste was added to the windrows. In 2022, RDKB expanded its feedstock capabilities to include biosolids.

PROJECT DETAILS

Site Name: Grand Forks Compost Facility

Ownership: Regional District of Kootenay Boundary (RDKB)

Location: Grand Forks, British Columbia

Start-Up Date: Projected February 2023

Product: SG BUNKER® System

Input quantity: 3,900 M-tons per year

No. of Heaps: 5 Heaps, 5 Covers, 20m x 6m x 2.7m each

Treatment Time: 8 weeks/batch in 3 phases:

Phase 1 (covered): 4 weeks

Phase 2 (covered): 2 weeks

Phase 3 (uncovered): 2 weeks

Aeration: In-Ground Trenching

Control Parameters: Oxygen Control Mode

Input Material: Biosolids, Source Separated Organics, Yard & Clean Wood Debris

Equipment: Pre-Treatment (Grinders) / Front-end-loaders / Mobile Screen / Water Truck

End Product: High-Quality Finished Compost

THE SG SOLUTION

Meeting Requirements While Producing High-Quality Compost

RDKB intends to produce two distinct Class A end products, including a compost with food scraps and yard waste, and a separate compost product with septage and biosolids. Two bunkers are dedicated to biosolids composting, and three bunkers are devoted to food and yard, and garden waste.

Of significant importance to the RDKB project was the SG BUNKER® System with GORE® Cover capability to comply with the state and local regulatory requirements and resource efficiency:

- Meeting air quality standards for Odor control

- Meeting Vector Attraction Reduction (VAR) requirements;

- Meet Time and Temperature requirements (PFRP) for pathogen reduction

- Produce high-quality finished compost

- Moderate composting processing time

- Low maintenance cost

PROJECT GALLERY

SG BUNKER® System at the Grand Forks Compost Facility

- SG BUNKER® System

- Commissioning of RDKB SG BUNKER® System

RESULTS DELIVERED

A Sustainable Solution with True Scale

Construction for the project is complete, and the site is fully operational.

Phase 1: COMPLETE – site work and construction portion of the project.

Phase 2: COMPLETE -Q1 2023– full-scale production launch of the 5-heap SG BUNKER® System with GORE® Cover.

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES Across the globe, a…

Celebrating the Season Without Wasting It

Celebrating the Season Without Wasting It The holiday season brings full tables, festive decor,…

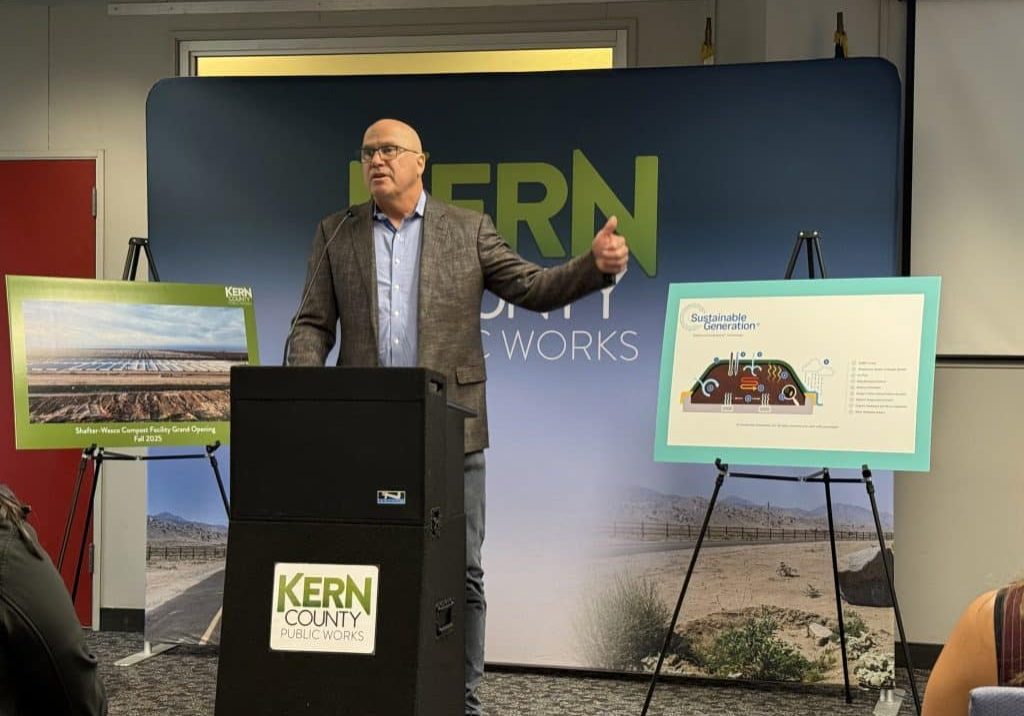

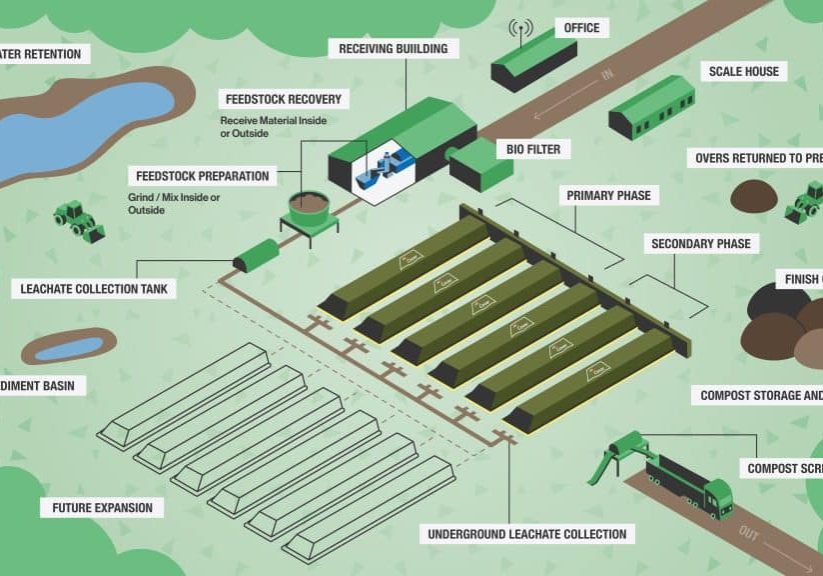

Building a Greener Future Together: Kern County Launches SG-Powered Compost Facility

Sustainable Generation is proud to celebrate the grand opening of the Shafter-Wasco Compost Facility

Making Waves, the Membrane Covered ASP Composting Tsunami

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.