Meeting California’s SB1383 requirements while proving the scalability and value of SG ADVANCED COMPOSTING™ Technology

As of 2014, Mid Valley Disposal had no previous composting experience and wanted to create a Compost Manufacturing Process capable of composting food waste.

PROJECT DETAILS

Ownership: Mid Valley Disposal

Location: Kerman, California

Start-Up Date: Demonstration: 2014 / Full Scale: 2017 / Expansion: 2020

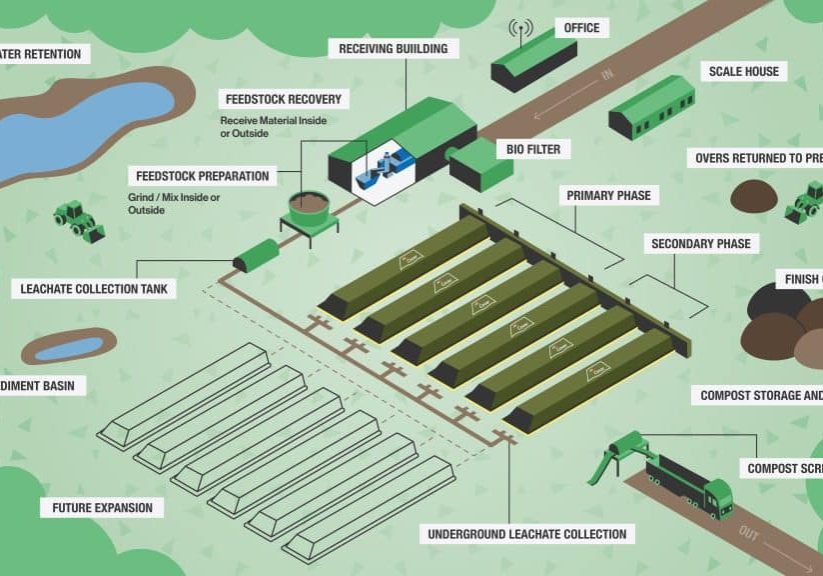

Product: SG BUNKER® System

Input quantity: 90,000 TPY

No. of Heaps: 24 Bunkers, 18 covered, 164 ft. x 27 ft. x 12 ft. each

Treatment Time: 8 weeks in 3 phases

Aeration: In-ground

Control Parameters: Oxygen Control Mode

Input material: Source Separated Organics / Yard Waste

Equipment: Pre-Treatment (Grinders) / Front-end-loaders / Mobile Screen

End Product: High Quality Finished Compost

FROM THEIR PERSPECTIVE

“We had no composting experience, so conducting a demonstration project with Sustainable Generation, LLC greatly enhanced our understanding of food waste composting and helped us immensely with our subsequent expansion design process. It made a difference, during the selection process, that SG’s technology was already a proven solution for meeting VOC emission reductions for our San Joaquin Valley Air Pollution Control District.”

– Jonathan Kalpakoff, VP Mid Valley Disposal

SG SOLUTION: Pilot-Scale Success Leads to Full-Scale Composting at Mid Valley Disposal

In 2014, Mid Valley Disposal (MVD) partnered with Sustainable Generation to launch a Pilot-Scale Demonstration Project using the SG MOBILE® System with GORE® Cover—a covered aerated static pile (ASP) composting solution. The pilot was designed to assess the performance of SG’s 8-week composting process and its effectiveness in processing food waste.

The project allowed MVD to evaluate:

-

Feedstock mix ratios and processing capabilities

-

Odor and VOC emissions control strategies

-

Operational feasibility and regulatory compliance

-

The viability of entering the organics recycling market

Located in California’s San Joaquin Valley, MVD needed a composting solution that could meet the region’s stringent air regulations, including Rules 4465 and 4466 for greenhouse gas (GHG) and VOC emission reductions, enforced by the San Joaquin Valley Air Pollution Control District. SG’s proven track record for regulatory compliance made the SG MOBILE® System the technology of choice.

The pilot project not only demonstrated SG’s ability to meet regulatory and operational goals—it also provided critical insights that shaped the design of MVD’s full-scale facility. The experience revealed the need for water addition in their hot, arid climate, prompting the integration of dedicated water piping in the permanent site design. The pilot also reinforced the importance of upstream material collection and source separation in ensuring composting success.

As a result of this successful pilot, MVD transitioned to a full-scale operation using the SG BUNKER® System.

PROJECT GALLERY

SG Bunker® System at Mid Valley Disposal

RESULTS DELIVERED

A Sustainable Solution with True Scale

Mid Valley Disposal’s full-scale facility was the first facility in the Central Valley for diverting large volumes of food scraps to meet California’s organic diversion mandates.

MVD received a $3 million grant from CalRecycle as part of the funding for their full-scale, 16-bunker, 60,000 TPY compost facility. CalRecycle, through its 2014-2015 Greenhouse Gas Reduction Organics Grant Program, awarded MVD the grant to help expand the infrastructure needed to recycle greater amounts of organic material in California.

In August 2017, MVD was awarded a second 2016-2017 CalRecycle grant in the amount of $1,875,000 through the same grant program to help with MVD’s 8-bunker expansion that was built and commissioned in 2020.

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES Across the globe, a…

Celebrating the Season Without Wasting It

Celebrating the Season Without Wasting It The holiday season brings full tables, festive decor,…

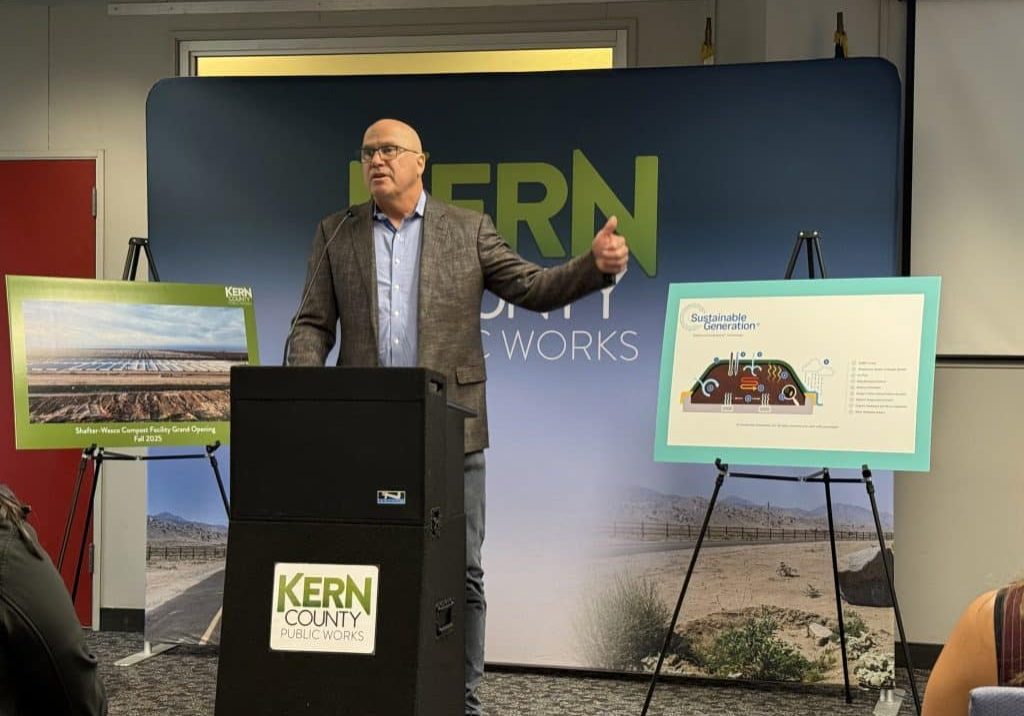

Building a Greener Future Together: Kern County Launches SG-Powered Compost Facility

Sustainable Generation is proud to celebrate the grand opening of the Shafter-Wasco Compost Facility

Making Waves, the Membrane Covered ASP Composting Tsunami

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.