PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES

Across the globe, a once-in-a-generation buildout of organics infrastructure is underway in both the public and private sectors. The facilities being designed right now will shape composting, hauling patterns, community expectations, and regulatory outcomes for the next 20–30 years.

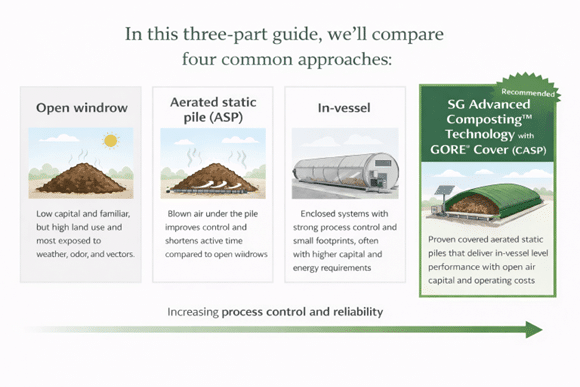

This article launches a three-part series on the true cost of composting technology decisions and why upfront price alone rarely tells the full story. Communities and operators are making infrastructure choices right now that will define how their sites perform, how smoothly they permit, and how much public trust they retain over decades.

Rather than focusing on initial capital cost, this series looks at what actually drives long-term performance and total cost of ownership over the lifetime of the facility, typically 20+ years. If you are planning or evaluating a composting project, this series will help you make decisions that hold up under real-world conditions, not just on paper.

Here’s the uncomfortable truth: Most composting projects don’t run into trouble because composting itself “doesn’t work.” They struggle because the process or technology selected can’t reliably deliver performance once real-world problems show up. When we talk with operators who have been through it, the same issues come up again and again.

Key Challenges to Consistently Meet Composting Performance Goals

- Close Proximity to Neighbors

- Tipping Fees That Leave Little Margin for Error

- Chronic Labor Costs and Shortages

- Increased Scrutiny of Stormwater and Leachate Management

- Tightening Air Quality and GHG Emission Regulations

This debate is not about a “technology preference”, it is a critical long-term risk management decision that could be the difference between a budget surplus and scrambling to find operating funds years down the line. Get it right and the facility can operate predictably for decades. Get it wrong, the costs show up later in the form of expansion delays, community opposition, retrofits, enforcement actions, and unplanned operating expenses that quietly erode the original business case.

We will show you how SG Advanced Composting™ Technology not only gives you a superior product but also gives a lower cost of ownership over time by using the same determining decision factors that industry leaders use every day: total cost of ownership, land efficiency, labor, permitting resilience, emissions/odor control, and water management.

The Mistake That Buyers Make Again and Again: Optimizing CAPEX Instead of Outcomes:

It is understandable why upfront price often drives purchasing decisions. Budgets are real, capital is finite, and composting facilities compete with many other priorities for funding and attention. On paper a lower initial cost can look like the prudent choice.

In practice, a low upfront price can become the most expensive decision you make when it leads to:

- Higher ongoing labor and operating costs

- Expansion delays or added compliance requirements

- Odor and GHG emissions issues that trigger complaints and enforcement

- Stormwater and leachate problems that require retrofits

- Reduced throughput, uptime, or usable capacity

When outcomes are sacrificed to minimized CAPEX, the cost does not disappear. It simply shows up later, after the facility is built, when the options to fix it are fewer, slower, and far more expensive.

Facilities that fixate on the capital cost often learn the hard way that buying the least expensive system, means that they have only put an initial investment on a costly headache that eats up money, manpower and is difficult to predict over time.

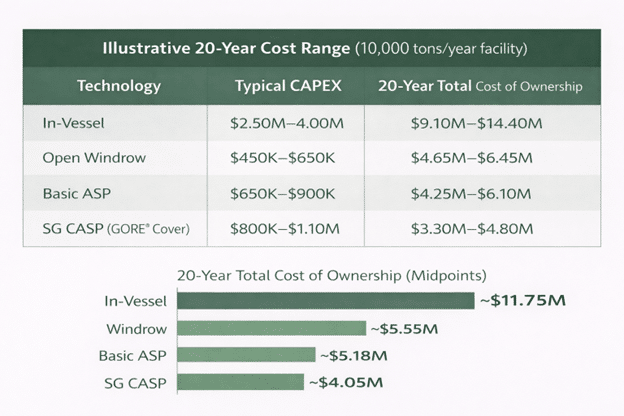

As the chart below illustrates, Sustainable Generation delivers a lower total cost of ownership over the life of the facility, even outperforming basic aerated static pile systems once real operating conditions are factored in. That advantage comes from designing for the full operating reality, not just day-one cost.

While some technologies are marketed as “faster,” composting still follows biological limits, and apparent speed often comes from shifting supposed time saving into hidden work later in the process, extra handling, or secondary equipment. When technology decisions focus too narrowly on upfront cost, operators frequently face rising labor demands, odor or emissions challenges, permitting risk, and costly retrofits later. SG offers a better path by addressing total cost of ownership, land efficiency, labor, compliance, and water management together, and by allowing operators to validate real-world performance through the SG Pilot™ Program before committing to a full-scale build-out.

In this first installment, we looked at why composting projects struggle not because composting fails, but because the chosen system cannot consistently perform under real-world constraints. We also highlighted a common mistake buyers make by prioritizing upfront capital cost over long-term outcomes.

In February, we will continue the series by taking the next step in the conversation and exploring how technology decisions shape performance and risk once a facility is up and running.

Contáctenos

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES Across the globe, a…

Celebrating the Season Without Wasting It

Celebrating the Season Without Wasting It The holiday season brings full tables, festive decor,…

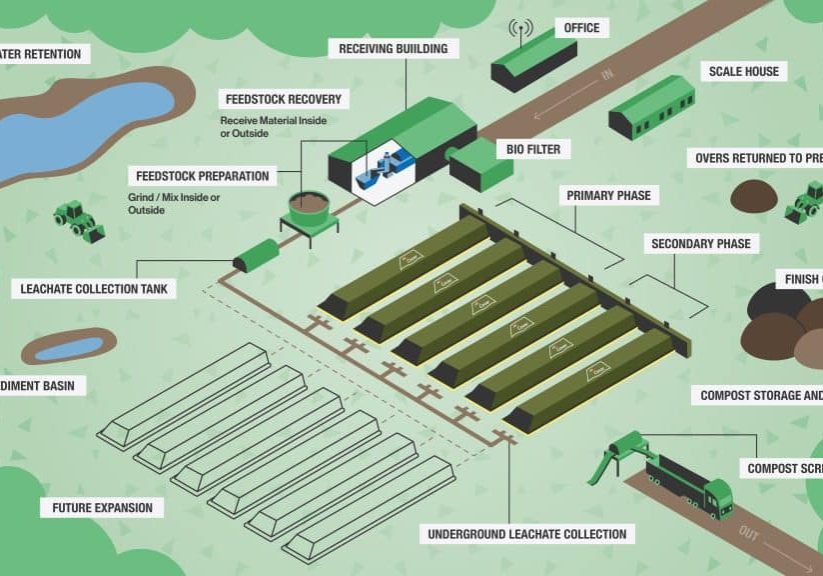

Building a Greener Future Together: Kern County Launches SG-Powered Compost Facility

Sustainable Generation is proud to celebrate the grand opening of the Shafter-Wasco Compost Facility

Making Waves, the Membrane Covered ASP Composting Tsunami

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.