SG BUNKER® System at MID VALLEY DISPOSAL Kerman, CA, USA

Making Waves, the Membrane Covered ASP Composting Tsunami

Two of the biggest issues faced by commercial composting operators are emissions (odor and VOCs) and moisture management. Odors and Volatile Organic Compound (VOC) emissions from compost facilities can be highly variable and are influenced by factors such as composting technology, feedstock mix, and operational parameters (initial grind, porosity, saturation, aeration, etc.). Moisture management issues are also complex, ranging from the moisture in the compost to managing the leachate and stormwater runoff, and are also influenced by feedstock mix and many of the same operational parameters.

Innovative Composting In Focus

Across North America, the clock is ticking on how we manage organic waste. Landfills are filling faster, emissions targets are tightening, and communities are being challenged to do more with less. The solution isn’t in bigger buildings or more complex machinery — it’s in smarter, cleaner, and more efficient composting systems.

As communities, states, and providences prepare for ambitious organics diversion goals; the spotlight is on innovative composting. Aerated Static Pile (ASP) systems, enhanced with highly engineered membrane covers, are revolutionizing the future of SSO composting.

Reducing the amount of organic waste sent to landfills by rolling out source separated organics (SSO) collection services to metropolitan households and businesses is a key waste diversion goal for many municipalities, states and providences in North America and elsewhere. With growing urgency, communities are facing mounting pressure to adopt scalable, reliable composting technologies for SSO.

Scott Woods, Founder and Chief Executive Officer of Sustainable Generation, explains that constructing large buildings with biofilters, to house composting operations are capital intensive, breeds complexity, and increase operational costs. In contrast, aerated static pile (ASP) composting has emerged as a practical, cost-effective, and high-performing solution

ASP basics

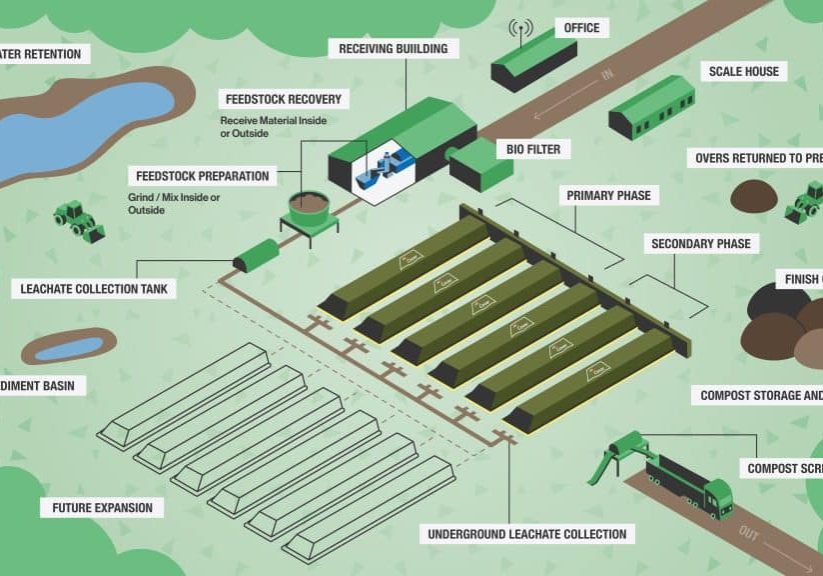

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity. There are two primary methods: negative aeration, which uses simple timed motors to pull air through the pile and exhaust through a biofilter; and positive aeration with temperature feedback. Developed in the 1980s, this method pushes air into the pile and uses real-time temperature monitoring to regulate blower activity, improving process consistency. Both approaches typically require a biolayer cap – 6 inches or more of woodchips or finished compost – to manage odors and retain heat. Scott says this traditional approach adds operational complexity and does not always deliver consistent results. The latest evolution in ASP systems involves highly engineered membrane covers that are semi-permeable, waterproof, and breathable. “These advanced systems offer in-vessel performance without the cost and complexity of enclosed facilities, consistently outperforming basic biolayer cap systems when evaluated on a true apples-to-apples basis,” he says.

The Department of Sanitation New York, Sustainable Generation system with GORE Cover membrane.

Image: Sustainable Generation

Covers v Non-covers

Biolayer caps are labor- and equipment-intensive. Applied on top of the compost mix recipe pile as a 6inch-to-2 foot layer, it provides insulation and odor control but requires a consistent application and frequent watering. Inconsistent cap thickness, improper application, or failure to apply the cap altogether can lead to odor problems and inefficient composting.

Brian Fuchs, Global Business Specialist at W.L. Gore & Associates, says engineered covers offer a visible, physical barrier that is easy to deploy and remove. He says that with a more than 25-year track record, GORE® Covers provide superior odor control, separate stormwater from leachate, regulate pile temperature, retain moisture, reduce greenhouse gas emissions, and improve compost quality – all while simplifying operations and reducing risk.

Performance limitations

Two biolayer-based ASP designs – low tech ASP with aerated floors using above grade piping, and extended mass bed ASP’s using in-ground sparger or trenching systems – are currently used for SSO processing. Brian says both can face performance limitations.

“They can only handle up to less than 20 per cent food organics, digestate, or biosolids by weight before odor complaints arise and require roofs to separate stormwater and leachate,” he says. “Moisture loss through the cap demands a dedicated watering system, and the cap reduces pile volume (thus capacity), consumes finished compost that could otherwise be sold, and introduces ongoing labor and operational costs. Uniformity in cap application is difficult to monitor, and inconsistencies compromise performance and emissions compliance.”

Lessons learned

Brian says recent failures at SSO facilities using aerated floor and mass bed ASPs reveal several recurring mistakes including:

- Underestimating feedstock complexity – assuming ASPs can handle high food organics concentrations without adequate odor control.

- Inadequate cap application – skipping the cap or applying insufficient depth (6 inches compared to the often needed 1 or 2 feet to contain odors).

- Ineffective moisture management – watering systems fail to penetrate the pile, drying out the core and requiring frequent turning.

- High energy consumption – negative air ASPs and single-blower manifold mass bed systems run continuously, consuming significant power and requiring complex components such as actuators, and variable frequency drives, increasing maintenance risks.

Setting the standard

Not all engineered fabric covers are the same. The performance of the GORE® Cover system, supplied by Sustainable Generation, is setting a new standard. Scott says using SG Advanced Composting™ Technology with Gore® Cover provides reproduceable outcomes include 90-99 per cent odor reduction for a recipe mix of up to 50 per cent (by weight) of food, biosolids, digestate, and other difficult feedstocks such as animal waste and mortalities. These results are backed by third-party, independent air emission studies.

“The GORE® Cover does not require a roof for separation of stormwater from leachate, delivering lower capital costs when compared to other ASP systems,” Scott says. Among other benefits, the cover prevents the spread of litter from feedstock contamination. Because the cover is sealed to the surface, pressurization occurs and prevents channeling and anaerobic pockets, delivering additional performance.

SG Advanced Composting™ Technology provides positive aeration with oxygen control and monitoring also provides energy efficiency by turning the blower on and off to meet the oxygen demand of the microorganisms that perform the composting process. Because the GORE® Cover is waterproof, moisture in the pile carries through the process, eliminating the need for a watering system.

Engineered for results

There are currently more than 400 installations of the GORE® Cover worldwide, with an annual processing capacity of more than four million tons. Scott says that as organics diversion mandates roll out, communities, operators, and project developers must invest in proven, scalable composting technologies.

“ASP systems with engineered covers – particularly those incorporating SG Advanced Composting™ Technology with GORE® Cover and positive aeration with oxygen control – are the clear front-runners,” he says. These systems offer unmatched performance, reliability, and cost-efficiency, making them the ideal foundation for the world’s next-generation organics recovery infrastructure.”

For more information, visit: www.sustainable-generation.com

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES

PART 1: COMPOSTING INFRASTRUCTURE DECISIONS THAT HAUNT BUDGETS FOR DECADES Across the globe, a…

Celebrating the Season Without Wasting It

Celebrating the Season Without Wasting It The holiday season brings full tables, festive decor,…

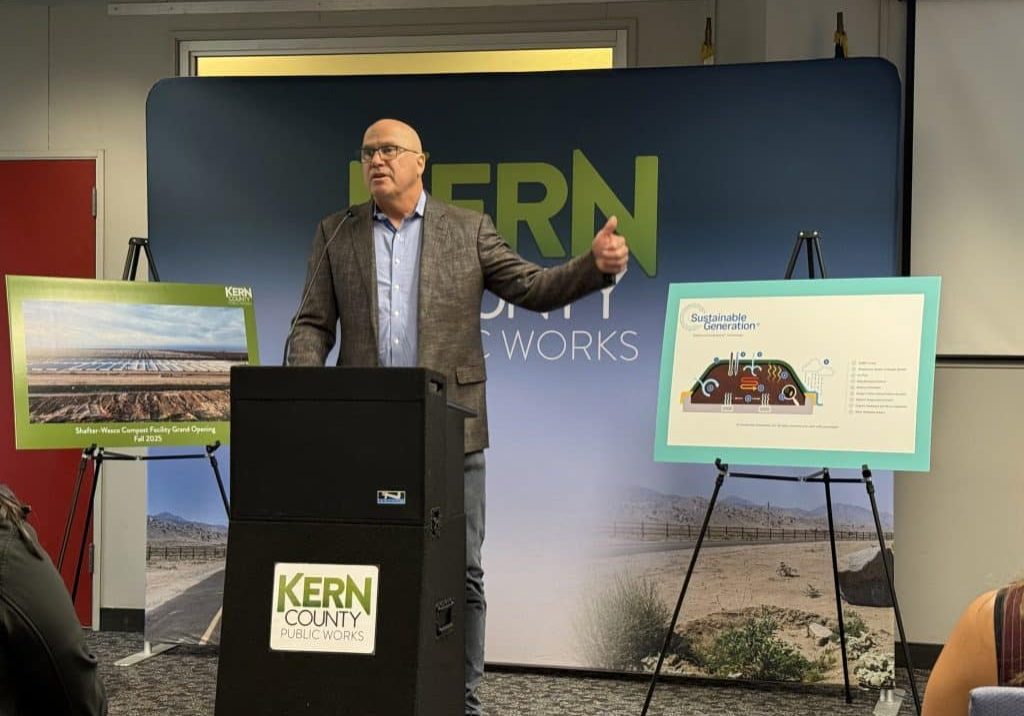

Building a Greener Future Together: Kern County Launches SG-Powered Compost Facility

Sustainable Generation is proud to celebrate the grand opening of the Shafter-Wasco Compost Facility

Making Waves, the Membrane Covered ASP Composting Tsunami

ASP composting relies on forced aeration to maintain aerobic conditions and optimize biological activity.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.