Summary of Performance GORE® Cover and Negative ASP

In 2003, the GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static pile. At that time of the test, the site processed 250,000 tons per year under negative air. Additionally, the same site also has a GORE® Cover processing up to 40,000 tons per year. For comparative purposes, the mix ratio is 4:1 by volume or 1:1 by weight of green to food waste was mixed at an equal ratio to make the technology comparison.

Description of existing operations on site at the time of this evaluation:

| Feedstock | System | Characteristics |

|---|---|---|

|

|

|

|

|

|

| Operation GORE® Cover | Operation NEGATIVE ASP | |

|---|---|---|

| Input: | 40,000 Tons Per Year | 210,000 Tons Per Year |

| Pretreatment: | Shredding | Shredding |

| Active Composting: | Active: 12 heaps Curing: 4 heaps |

Active: 7 heaps Curing: 12 heaps |

| After-treatment: | Screening | Screening |

Comparison of the time required to meet finished compost:

| GORE® Cover | Negative ASP | |

|---|---|---|

| Initial Placement | 30 days | 15 days |

| Second Placement | 15 days | 15 days |

| Third Placement | 15 days | 15 days |

| Aging | 30 days | 270 days |

| Total Treatment Time | 90 days | 305 days |

Critical Observations

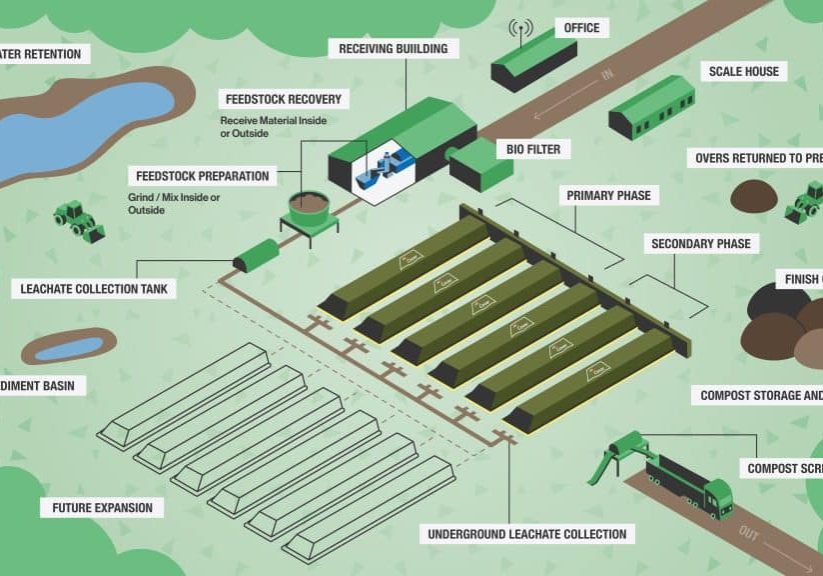

The technology upgrade on site to the GORE® Cover utilized existing structures and developments of the existing and previously developed site.

The GORE® Cover technology is more cost-efficient than the existing negative aeration system; the GORE® Cover process uses significantly less energy to produce the same product. Energy consumption will be reduced by up to 10 times.

The GORE® Cover finished compost is available to sell within 8 to 12 weeks as opposed to 7 to 12 months in the case of the negative ASP. This allows the overall storage pile volumes to be decreased at the site, saving considerable space.

One additional point of focus is on the reduction of odor, VOC, and ammonia. Not only are the odor, VOC, and ammonia releases substantial in the negative air system, but it also indicates that nitrogen, a component of ammonia, is lost in the negative air system, thus not being reintroduced into the finished product. By using the GORE® Cover, up to 90% of the odors are reduced, up to 95% VOC emission reduction is achieved and ammonia is practically non-detectable which means much higher percentage of ammonia is fixed into beneficial nitrogen compounds that end up in the final compost product being sold rather than released to the atmosphere. Nitrogen values in the GORE® Cover finished compost have increased from 50% to 100% compared with the negative air system.

Microbial activity in the compost is very important. After only a short aging of GORE® Cover material, the microbial diversity in 8-12 weeks in Gore is comparable to 9-month-old compost from the negative air system.

One added benefit of the system was the ability to increase the temperature of the process up to 180 degrees F to deal with pathogen issues and readily break down compostable products. That temperature increase should not affect the microbial diversity. After testing the finished product, it was concluded that the diversity was not affected.

The GORE® Cover decreases the impact of rain/snow events. This region can get up to 54 inches of rain per year. On some rainy days, with 1 to 2 inches in 24 hours, would cause the negative air system issues and the piles can go anaerobic. The GORE® Cover keeps unwanted moisture off the piles, thus the system works better and is more productive because of not need to deal with adverse climate effects. Conversely, for very dry late summers, there is no moisture for months. It is important to have the GORE® Cover maintain the moisture in the piles and requires less water added between movements of the material.

The site gets high winds in the winter, gusting up to 70 mph. The GORE® Cover stayed on during these events and also reduced litter around the site by staying under the cover.

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.