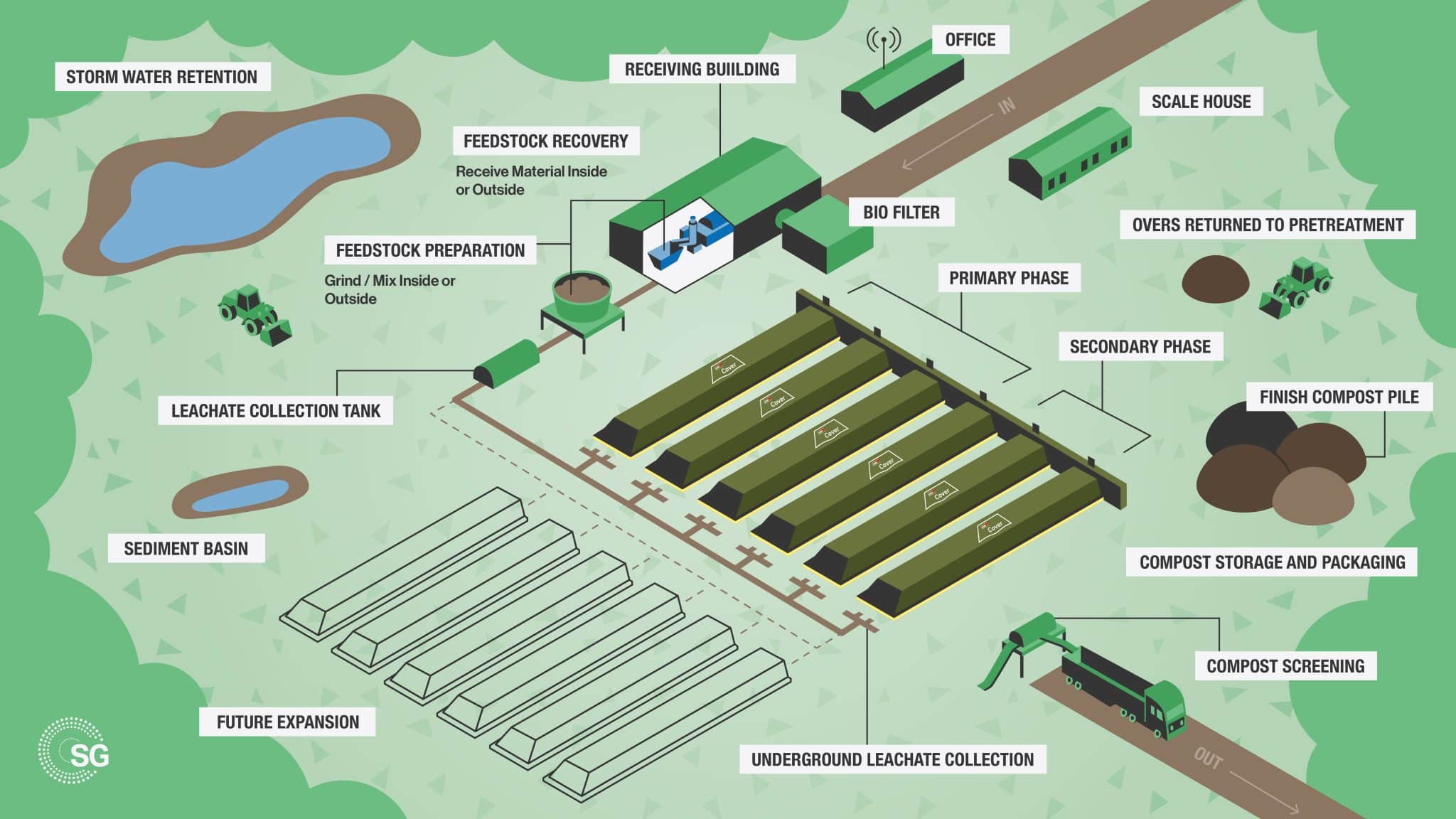

How our composting technology works

Smart design. Proven performance.

Our covered aerated static pile (CASP) system, enhanced with the GORE® Cover, accelerates the transformation of diverse organic materials—like food, yard, and biosolids—into high‑quality compost. This proven approach delivers precise control over temperature, moisture, and blower metrics, ensuring regulatory compliance, minimal environmental impact, and consistent performance. Whether you're designing a new facility or optimizing an existing operation, SG's expert team guides you through every step—from site layout and system setup to monitoring, reporting, and final product optimization—so you can focus on efficiency, sustainability, and scale.

FLEXIBLE DESIGN

- Our modular, expandable technology is repeatable for standard and customized designs – scalable from 1 heap to +100 heaps.

TREATMENT COSTS PER TON

- Treatment cost per ton is lower compared to other systems because of the simplicity of design with few moving parts and low energy consumption.

SMALL FOOTPRINT

- A throughput capacity of 4 - 8 weeks vs. a windrow of 8 - 12 months allows more material to be processed on a smaller site.

- Full-scale operations on as little as a half acre.

LOW ENERGY CONSUMPTION

- SG's covered aerated static pile design has lower energy consumption compared to negative aeration, reverse aeration, and timed positive aerated systems.

- SG's use of proprietary remote oxygen and temperature control system technology makes for the most cost-efficient processing.

- Also reduces or eliminates the need for a costly, high-energy consumption biofilter.

SIMPLE TO OPERATE

- Fewer moving parts.

- Can be operated by one person.

- Less than one operator is required for every 10,000 tons processed yearly.

EFFECTIVE IN ALL CLIMATES

- Encapsulated technology is not influenced by weather or climate and does not need an enclosed building.

- From the arid heat of the Mohave Desert to Finland’s subzero snowy climate, SG’s solution is a proven winner in any climate. Hot, wet, dry, and subfreezing applications.

ODOR REDUCTION

- Reduces odors 90-95% as compared to open or uncovered systems and without the need for a compost cover layer.

EPA 503 EQUIVALENCY COMPLIANT

- Our solution meets the EPA 503 regulations for PFRP and vector attraction reduction (VAR) without the use of a foot compost cover layer.

VOC EMISSION CONTROL

- Controls > 95% of VOC emissions.

- Meets tough SB1383 and similar standards

STORMWATER LEACHATE MANAGEMENT

- The SG process offers a clear separation of stormwater and leachate.

- No need for a building or roof.

- Faster permitting, less infrastructure expense, and smaller footprint.

MOISTURE MANAGEMENT

- Once the proper 55%-65% moisture content is achieved on the initial mix recipe, our solution manages the moisture throughout the entire process with no need to add additional water to maintain proper moisture in the process.

REGULATORY COMPLIANCE MANAGEMENT

- Automatically gathers all the regulatory data needed. Monitors temperatures by date, time, and heap to produce regulatory reports for you.

- Helps make the reporting process easier.

COMPOST QUALITY

- Achieves the highest quality product in as little as a 6-8 week process, giving you the ROI you are looking for, regardless of the feedstock.

- Agricultural-grade compost can be produced in as little as 4 weeks.

COMPLIANCE FACTS

- Pathogen Reduction and Hygenization

- Meets PFRP, VAR, Hygiene, and ABPR EPA 503: Alt 5: Use of PFRP [503.32(a)(7) and (B)(1) of Appendix B]

- Effective Odor Control for Good Air Quality - Odor reduction 90-95% (Odor emission study)

- VOC emission: US/Cal: > 95%, thus California Compliant for 80% (acc. to Rule 1133.3, Rule 4565, Rule 4566 & BACT)

- Greenhouse Gas Control

- Lowest possible emission rate (CO2 equivalent) compared to all other technologies

- Dust and Bioaerosol Control Bacteria retention > 99%, e.g. Aspergillus fumigatus

- Dust and Particulate Matter (PM) Retention > 99% (Thesis Dr. Kühner: Emission Study ) Water Protection

- Waterproof GORE® Cover Protection from groundwater contamination

- Clear separation of leachate from stormwater

Smarter Aeration

Air Is the Engine of the Composting Process

Our systems use precise, computer-controlled positive aeration to deliver optimal airflow throughout the pile. The result is consistent temperature, oxygen, and moisture across the batch, driving rapid pathogen reduction and compost stabilization.

Key Features

Analyze Blower Metrics

Energy-efficient fan cycles

In-ground trenching or on-grade pipe

Custom configurations for every site

Integrated Performance

A Complete, Closed-Loop Process

From aeration to compost curing, SG ADVANCED COMPOSTING™ Technology delivers high-performance results that are third-party certified and climate-resilient.

Rapid PFRP and VAR compliance

High-quality, saleable compost

Reduced Odors, neighbor-safe, permit-compliant

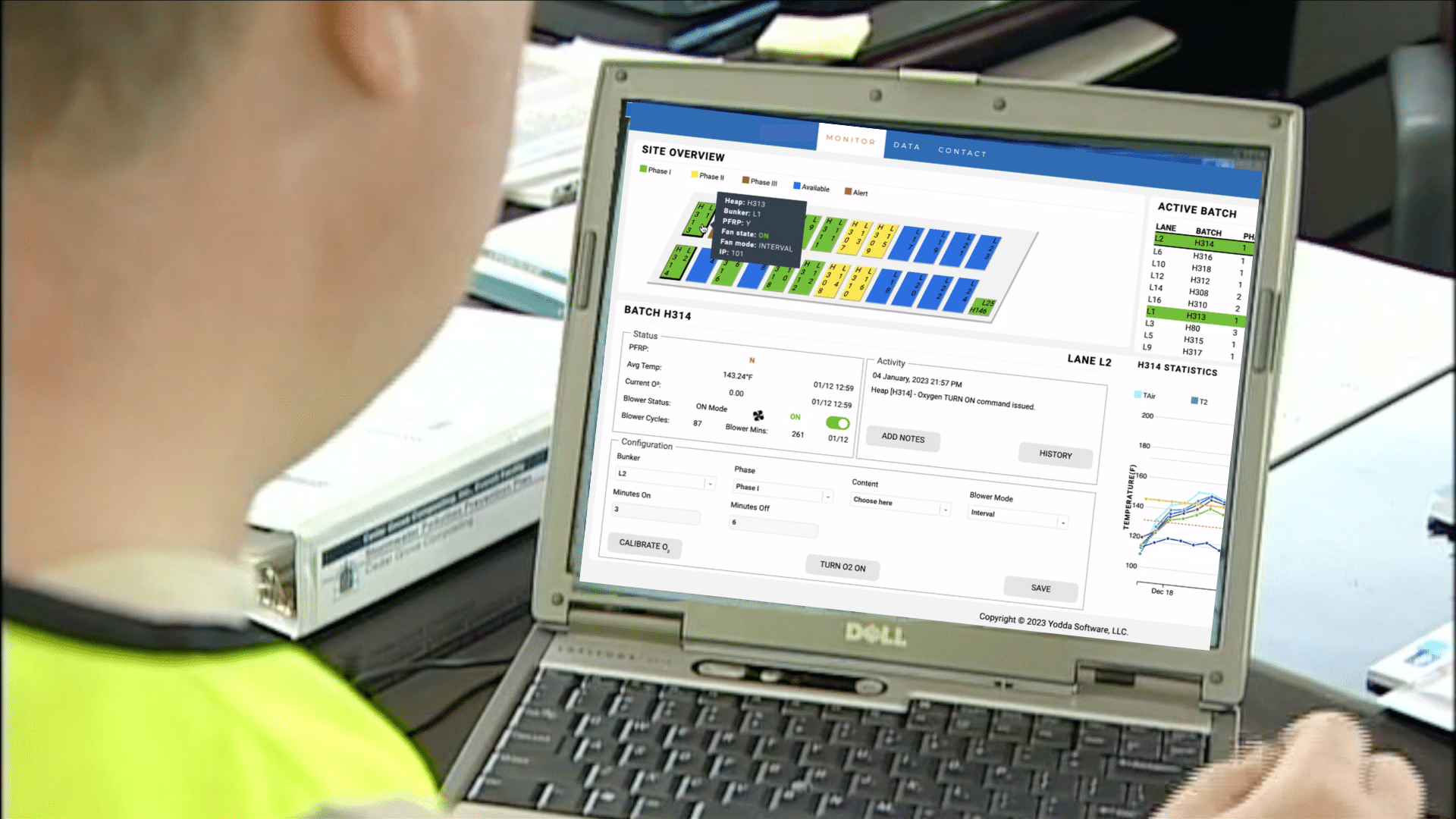

Monitoring That Makes the Difference

SG Compost Control™ System, Designed by Operators for Operators

The SG COMPOST CONTROL™ System is a proprietary cloud-based platform that lets you monitor and adjust your piles from your laptop or mobile device in real time.

-

View temperature, oxygen, blower metrics, and status

-

Configure individual batches for each Bunker / Heap

-

Export data for regulatory reporting

-

Get alerts when action is needed

Layouts That Fit Your Facility

Modular Designs, Ready for Any Site

Choose the system layout that fits your feedstock, capacity, and footprint.

SG Mobile® SYSTEM

Best for pilots, small-medium sites, or off-grid use

SG Bunker® SYSTEM

High-throughput permanent installations

SG Heap® SYSTEM

Simple, scalable processing