Composting biosolids has become a crucial practice in resource recovery and environmental stewardship.

But how does the process work? What distinguishes biosolids from traditional organic composting? And how can municipalities, businesses, and policymakers better support the responsible use of composted biosolids?

In this interview with Biosolids Consultant Dan Collins, P.E., we explore the science, regulations, and innovations shaping the future of biosolids composting. We discuss the essential parameters that ensure pathogen-free, high-quality compost and the latest technological advancements that reduce processing time and environmental impact. This discussion covers everything you need to know about utilizing biosolids for a healthier planet.

Can you walk us through the composting process for biosolids and explain how it differs from traditional organic composting?

Dan: Biosolids are dense and typically high in nitrogen, requiring a proper blend with a carbon additive. Wood chips are a preferred additive feedstock, providing the porosity required to allow for proper air flow throughout the mix, creating an atmosphere ideal for the microbes. However, determining a proper blend of biosolids to additive takes a bit a calculating due to the moisture content of the biosolids ranging from 12-30% total solids, typically. While the range of solids content may be a challenge, biosolids tend to be free of physical contamination such as plastics, metals, and other debris, often found in other organics. Biosolids must be free from many other contaminants, such as forever chemicals (PFAS, PFOAS) and pharmaceuticals, before being applied to land to ensure safety.

Biosolids must meet stringent regulations before composting to ensure safe compost is generated for public use. Biosolids must meet EPA regulations for various contaminants, such as metals, pharmaceuticals, and other chemicals, in order to qualify for land application, even before composting.

Facilities composting “clean” biosolids realize that their product is very consistent in percent solids, allowing them to have a very efficient program, and thus making it very easy to create a stable, mature soil amendment.

What are the key parameters—such as temperature, moisture, and retention time—that ensure high-quality and pathogen-free composted biosolids?

Dan: It is important to create a biosolids mix with the ability to maintain proper aeration to allow for temperatures above 55 °C to be achieved for a minimum of three consecutive days to kill off pathogens to a Class A level. Maintaining moisture content between 45-60% ensures aerobic conditions are present and allows for bacteria and microorganisms to convert the biosolids into compost by consuming nutrients that are dissolved in the water molecules. Other parameters for composting are PH between 6 and 8, carbon to nitrogen ratios of 25-35:1. The amount of time to create a stable and mature compost is affected by the composting process chosen. Windrow turning operations typically have a much longer process time than in-vessel composting and aerated static pile composting.

How do composted biosolids contribute to soil health and carbon sequestration, and how do they affect sustainable land management?

Dan: Composted biosolids contribute to soil health and carbon sequestration by adding organic matter to the soil, which improves its water retention capacity, resulting in better plant growth and their ability to remain healthy during droughts. Biosolids are rich in nutrient content such as nitrogen, potassium, and phosphorus, as well as many other macro and micro nutrients. Applying composted biosolids to land reduces the need for chemical fertilizers. In addition, the carbon found in composted biosolids is sequestered in the soil, again, reducing the need for chemical fertilizers. Composted biosolids are a good food source for microbes in the soil and therefore improve microbial activity and the overall health of the soil. Applying composted biosolids is a key to sustainability and nutrient recycling.

What are the most important regulations governing biosolids composting, and how can policymakers support responsible and beneficial use?

Dan: The most important regulations governing biosolids composting are 40 CFR Part 503, developed by the EPA.

Adhering to the regulations as outlined and then testing to ensure pathogen reductions and that stability and maturity conditions have met USCC standards supports responsible and beneficial reuse. Policy makers can work to pass legislation to ensure these valuable products are kept out of the landfill, along with many other organic feedstocks. Creating compost from organics can have an impact on the lifespan of landfills and improve the condition of our soils around the world. Legislation to utilize these compost products on agricultural land, DOT projects, parks, and recreational facilities, etc., will have a major impact on their use.

What are the biggest challenges—whether regulatory, operational, or public perception—that hinder the adoption of composted biosolids, and how can we address them?

Dan: The challenges in the adoption of composted biosolids are related to the lack of education on the benefits and proper use of the product. Composted biosolids improve the health of soil by adding macro and micro nutrients, which have slowly been depleted over decades of farming. In addition, composted biosolids improve the ability of the soil to retain more moisture, reducing flooding. Regulations assist agencies with contaminant-free biosolids to keep the product out of the landfills by utilizing them on parks and recreational facilities, golf courses, and other turf applications. Better education and testing of biosolids prior to use to ensure safe application is essential. However, some of the biggest challenges come from poor operations, resulting in poor overall product quality, such as aesthetics, odors, etc. Operations providing an inferior product hurt the entire industry. As the saying goes, “One bad apple spoils the bunch!”. Having an Environmental Management Program for biosolids, such as the EPA’s ISO14001 program or the Water Environment Federation’s National Biosolids Partnership program, can assist in ensuring best management practices are followed.

What recent technological innovations or best practices have improved the efficiency and environmental impact of biosolids composting?

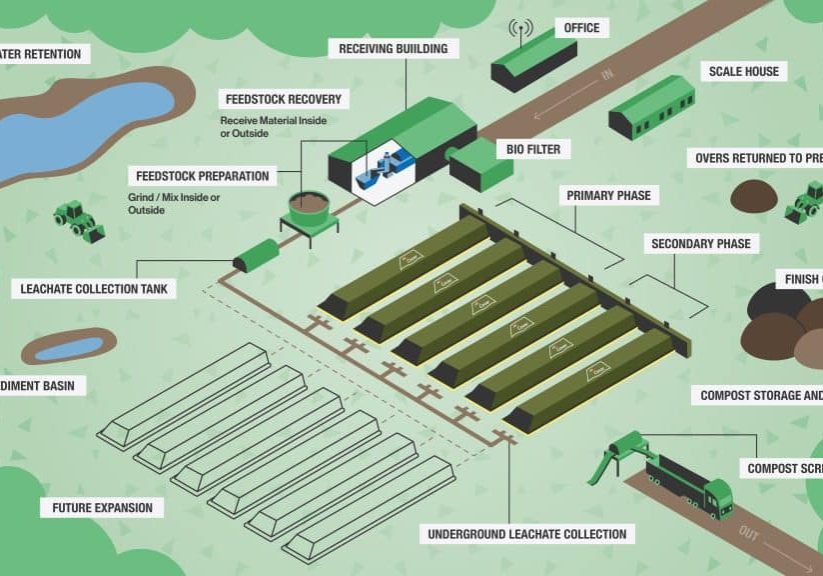

Dan: Composting has evolved over the past couple of decades. The three primary methods of biosolids composting, windrow, aerated static pile, and in-vessel technology, have all seen improvements. Windrow machines have become larger and more efficient, with the capabilities of adding water or cover placement. Aerated technologies have seen changes in many ways as well. There are positive, negative, and reversing air technologies available with or without the use of biofilters and compost “caps”. Caps refer to some type of cover to reduce odors, VOC emissions, and greenhouse gases. Caps can be in the form of a layer of 12-18 inches of biomass or a semi-permeable membrane cover. A semi-permeable membrane cover used with positive aeration requires no biofilter as the cover provides odor control. In-vessel technologies are completely enclosed with augers, conveyors, rams, or other devices used to aerate, mix, and move the product to a discharge point.

Other innovations include the use of real-time oxygen and temperature sensors to improve aeration efficiency, thus reducing costs. By monitoring the conditions in real time, aeration intervals can be set to create optimal conditions for microbial activity necessary to kill off pathogens and reduce the amount of time required to create a nutrient-rich soil amendment.

Each of these technology advancements, and others, contributes to shorter composting times, better quality products, and reduced environmental concerns associated with biosolids processing and utilization.

How can municipalities, businesses, and sustainability advocates better educate the public on the safety and benefits of using composted biosolids in agriculture and landscaping?

Dan: Educational events provide a great avenue for the public to see the product and product results while teaching about the product’s uses in community gardens, parks, etc. Outreach is key to the success of any biosolids program. It is important to educate the public on the safety of properly created biosolids and biosolids products, such as compost. By educating the public on the stringent regulations and monitoring of composted biosolids, we are investing in waste reduction, resource recovery, pollution mitigation and sustainable practices. Public awareness plays a key role in the success of any biosolids program. When the public can see how the composting biosolids creates opportunities to keep landscape waste and other organic feedstocks out of the landfill, a vision for sustainability and partnership can be realized.

Facilities that compost biosolids can benefit from an Environmental Management (EMS) Program. An EMS is a framework to identify and act on opportunities to improve in areas of environmental performance, regulatory compliance, quality management practices, and relations with interested parties and other stakeholders. In addition, an EMS helps identify critical areas for improvement in efficiencies and overall product creation. Municipalities, businesses, and sustainability advocates can work together through these types of programs to better educate the public on the safety and benefits of using composted biosolids in agriculture and landscaping.

Daniel Collins, P.E.

Biosolids and Organics Consultant

Dan Collins is a veteran in biosolids management and organics recycling, bringing over three decades of experience in wastewater treatment, solids handling, and composting strategy. As a licensed Professional Engineer in Illinois with a degree in Mechanical Engineering from Purdue University Northwest, Dan has devoted his career to transforming how municipalities view and manage organic waste.

Dan began his career with the Metropolitan Water Reclamation District of Greater Chicago (MWRDGC) in 1987, rising from intern to Section Head of the Biosolids Division. There, he led efforts to eliminate landfill disposal of biosolids, reduce operating costs, and launch a successful composting program, culminating in the district earning Platinum Certification from the National Biosolids Partnership.

Since 2017, Dan has served as a consultant for Sustainable Generation, LLC and GORE® Cover, as well as firms such as Greeley and Hansen, Donohue & Associates, Brown and Caldwell, and Material Matters. His work focuses on feasibility studies, master planning, and full-scale implementation of composting programs for wastewater treatment plants (WWTPs), guiding clients toward Class A, odor-free biosolids products.

A strong advocate for compost’s environmental and economic value, Dan uses a triple-bottom-line analysis to help clients make informed decisions about resource recovery. He’s especially passionate about demonstrating how compost offers long-term soil benefits through its macro- and micronutrient content, providing a sustainable alternative to conventional fertilizers.

Dan’s proudest professional achievements are helping launch MWRDGC’s composting program, earning his PE license, and mentoring the next generation of wastewater professionals. He’s proud of his family and enjoys raising three children with his wife.

Dan is driven by a desire to give back to the world through his work. Whether developing pilot projects or supporting full-scale composting operations, he is energized by collaboration with like-minded professionals and motivated by the integrity and vision of the teams he supports. Outside of work, Dan focuses on efficiency and environmental stewardship in his personal life, continually looking for ways to improve systems and share knowledge with others.

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.