Addressing the Challenges and Opportunities of Depackaged Food Waste in Composting

This is an in-depth interview with our Technical Manager – Service and Sales in Canada, Aaron Osczevski, to discuss composting depackaged food waste with our SG ADVANCED COMPOSTING™ Technology.

Here is what he had to say

Can you elaborate on the specific challenges that depackaged food waste presents for composters?

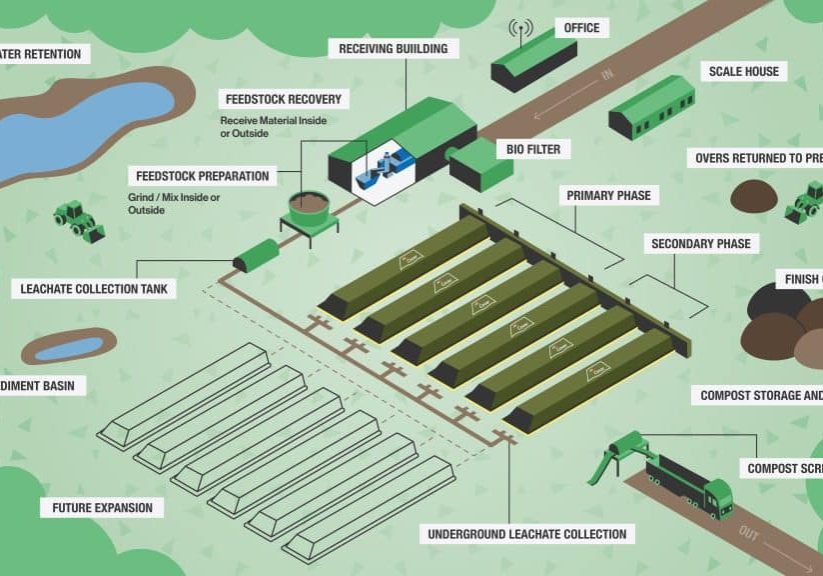

Aaron: Certainly. Depackaged food waste poses several challenges for composters. It’s a highly wet and dense material, requiring a significant amount of bulking agent to achieve the right porosity. However, many sites struggle to bring in enough bulking agents, complicating the process of ensuring proper moisture levels and porosity.

Another challenge is odor. Feedstock like food waste can vary seasonally, very much like SSO. In Canada, it is the most consistent feedstock that composters can add to their system. Adding food waste to your stream will certainly add odor to your site; however, I know a lot of sites across North America and Oceania that utilize SG ADVANCED COMPOSTING™ Technology to help keep odors at a minimum, as well as keep labor costs low.

What innovative methods or technologies have you seen being utilized to address the issue of depackaged food waste in composting facilities?

Aaron: I have extensive experience using depackaging separator equipment that effectively separates contaminants from food waste, resulting in a clean material that can be easily incorporated into composting systems. Mixing the separated material into our SSO/Yardwaste stream helped maintain moisture levels and minimize contamination in our compost.

I have extensive hands-on experience operating SG systems in one of the most extreme climates in North America. Despite temperatures ranging from -40°C in winter to +40°C in summer, we successfully composted food waste year-round. Even under these harsh conditions, we consistently achieved premium compost quality, demonstrating the system’s reliability and performance across all seasons.

In your opinion, what are the potential environmental benefits of diverting depackaged food waste from landfills and incorporating it into the composting process?

Aaron: Diverting depackaged food waste from landfills and composting offers significant environmental benefits, particularly in reducing greenhouse gas emissions. Anaerobic digestion of food waste in landfills generates methane, a potent greenhouse gas. Composting, on the other hand, mitigates these emissions while producing nutrient-rich compost that improves soil health.

How important is a collaboration between different industries and stakeholders in finding comprehensive solutions to the challenge of depackaged food waste?

Aaron: Collaboration among industries and stakeholders is paramount in addressing depackaged food waste. By working together to implement effective waste diversion strategies, we can reduce the burden on landfills and create a more sustainable future.

What role do you believe education and outreach play in addressing depackaged food waste, and how can consumers be empowered to make more sustainable choices?

Aaron: Education is crucial in empowering consumers to make sustainable choices. Providing information about the environmental impact of packaging and food waste encourages consumers to prioritize eco-friendly products and disposal methods.

Looking ahead, what do you see as the key drivers of progress in effectively managing depackaged food waste and creating a more sustainable food system?

Aaron: Sustainable packaging solutions at the pre-consumer level will be essential in reducing food waste and promoting a more sustainable food system. By minimizing packaging waste, we can streamline the composting process and reduce overall environmental impact.

Can you share any success stories or examples of composting facilities effectively handling depackaged food waste, and what lessons can be learned from their experiences?

Aaron: At Loraas, we utilized a separator and an SG System to process commercial food waste, yielding nutrient-rich material that enhanced our finished compost. This approach simplified operations, improved compost quality, and contributed to overall sustainability goals. The lesson learned is that innovative technologies can play a crucial role in maximizing the benefits of depackaged food waste in composting operations.

Aaron Osczevski

Sustainable Generation Technical Manager – Service and Sales

Aaron boasts over 10 years of experience in the waste and organics industry, serving in various capacities including operator, lead hand, and supervisor. Previously, he held the position of Organics Supervisor at Loraas Disposal North (Waste Connections of Canada), where he managed a 24,000-tonne-per-year SG ADVANCED COMPOSTING™ Technology facility catering to the Greater Saskatoon area. Aaron specializes in cold-weather composting, having operated in temperatures as low as -40°C while maintaining quality standards. He joined SG in February 2024 and remains an active member of the Compost Council of Canada, holding a Certified Operator certificate through the CCC. Aaron’s notable achievements include obtaining a Project Management certificate, Heavy Equipment Evaluator certification, and a Bachelor’s degree from the University of Alberta.

Contact Us

Our Blog

Projects, Technology, and News

Explore our blog to discover more about our projects, technology advancements, and exciting news.

INTERVIEW WITH A BIOSOLIDS EXPERT

Biosolids expert Dan Collins, P.E., shares insights on safe, efficient composting.

Summary of Performance GORE® Cover and Negative ASP

GORE® Cover was evaluated to quantify the performance versus an existing negatively aerated static

Composting Facility Delivers Significant Environmental Protection

The East Coast’s largest food waste composting site processes 57,000 tons of organics annually.

Exceeding Air Quality VOC Emission Regulatory Compliance in California

SG systems consistently meet and exceed California air quality regulations.

Positive ASP Composting: the Future of Organics

Two of the biggest issues faced by commercial composting operators are emissions (odor and

Proven Results: Over 20 Years Reducing Odors and Emissions in California

Sustainable Generation, LLC and the GORE® Cover have a long track record of success.

Why Smart Composting Facility Operators Keep Stormwater and Leachate Separate

During heavy storms, composting facilities face increased runoff and leachate.